KASHYAP: impulse frequency descaler

To remove existing scales and fight further scale deposition in a AHU Nozzles Before Kashyap mineral descalers were installed at the company's Textile Division; the Spinning Plant would have to deal with very high mineral scale content/ hardness level of 29 GPG (500 PPM). After the Kashyap installation when mineral hardness content would reach as high as 57 GPG (975 PPM) all piping, nozzles and AHU sheets woudl strill be clean and free of scale build-up.

Installed Models:

1 x K-25011 x K-50

2 x K-25

The purpose of installing the Kashyap mineral descaler was to:

- Prevent mineral scale deposits

- Prevents from loss

- Improve heat exchanger efficiencies

- Reduce Air Handling Unit (AHU) sheet, pipes and nozzles maintenance and cleaning costs

After a few months the Kashyap mineral decalers were able to soften the cooling tower and AHU’s nozzles; scale in the pipes become soft and maintenance crews could remove the existing scale build-up with normal brushing.

K-50 Model

Before installation

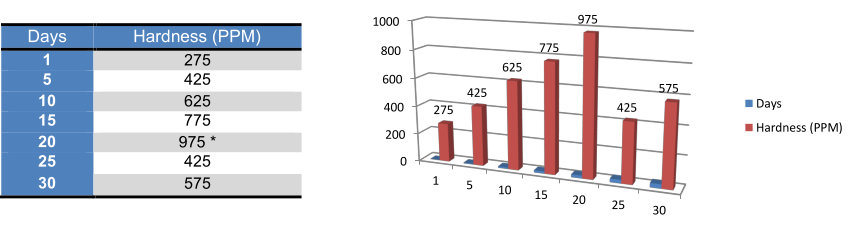

Before Kashyap installation heavy scale depositions on 29 GPG (500PPM) of hardness level, but after Kashyap installation, on 57 GPG (975 PPM) of hardness level all piping, nozzles and AHU sheets are clean. *On 20th day (975 PPM) a blow down was initiated; meaning there was an 80% water change in the AHU tank (Air Handeling Unit).

Before Kashyap installation heavy scale depositions on 29 GPG (500PPM) of hardness level, but after Kashyap installation, on 57 GPG (975 PPM) of hardness level all piping, nozzles and AHU sheets are clean. *On 20th day (975 PPM) a blow down was initiated; meaning there was an 80% water change in the AHU tank (Air Handeling Unit).