Models: K-250 | K-500

Location: Gandhinagar, Gujarat (India)

Installation Area: Cooling Tower’s Circulatig Pipe, BFP Cooler Inlet, Oil Cooler, Condenser Tubes

leading manufacturers of forged and machined components in India

www.gsecl.in

Location: Gandhinagar, Gujarat (India)

Installation Area: Cooling Tower’s Circulatig Pipe, BFP Cooler Inlet, Oil Cooler, Condenser Tubes

leading manufacturers of forged and machined components in India

www.gsecl.in

KASHYAP: impulse frequency descaler

3 impulse frequency mineral descalers were installed at this power plant to prevent scaling inside cooler tubes for the purpose of improving efficiency and lowering mechanical cleaning and maintenance.Nameplate Capacity: 870 MW

Units Operational: 2 X 120 MW; 3 X 210 MW

Kashyap Technology:

1 x K250 for #3 BFP Cooler inlet,

1 x K500 for #4 ACW line to TG tube oil cooler

1 x Customized descaler unit a 63 inch pipe diameter protecting the condenser tubes

K-250 mineral descaler

K-500 mineral descaler

Kashyap mineral descaling technology can be custom produced to adapt to large scale pipe diameters. This power plant in India required a custom solution for their 63 inch condenser pipe to protect against scale and rust.

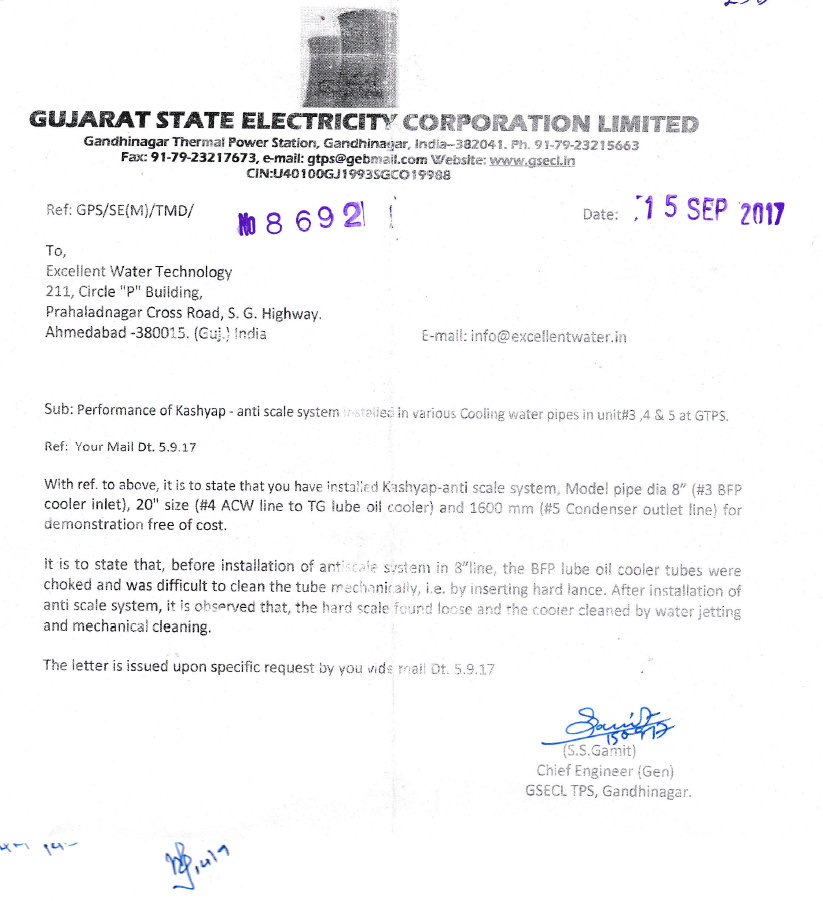

S.S. Gamit

Chief Engineer (GSECL TPS, Gandhinagar)

“It is to state that, before installation of anti-scale system on 8 inch line, the BFP tube oil cooler tubes were choked and was difficult to clean the tube mechanically, i.e. by inserting hard lance. After installation of anti-scale system, it is observed that, the hard scale found loose and the cooler cleaned by water jetting and mechanical cleaning.”