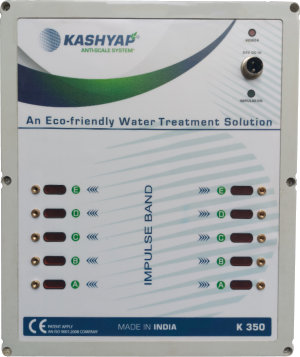

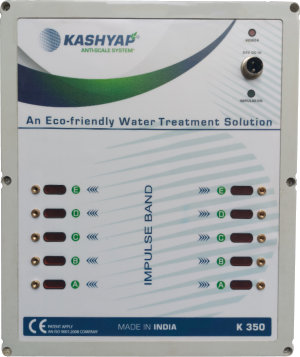

Hard Water Descaler

MAINTENANCE-FREE

100% ECO-FRIENDLY

NO CHEMICALS, SALTS OR MAGNETISM

WORKS ON ALL PIPE MATERIALS

Technology

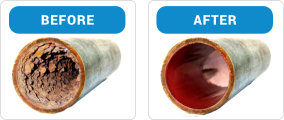

Calcium and magnesium minerals in water are essential for plants, animals and people however these minerals stick to surfaces restricting water flow, causing corrosion, and require extra energy from appliances to maintain the same performance; such as water heaters.Impulse Frequency Control Board

The circuit board is very energy efficient and only uses 2.75 watts of energy; about $25 per year in energy costs. It creates the frequency impulses and the programming of how these 3-32 KHz frequencies are used to change mineral bonds into rod-shaped structures. This prevents new scale from being formed and removes existing scale from your water pipes, in your appliances and equipment, and off of heating elements.

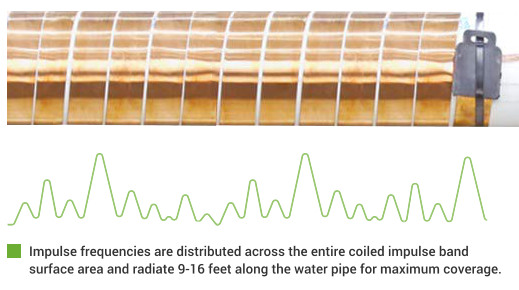

Impulse Frequency Copper Bands

The impulse bands are an essential part of the descaling process. The thin, flat bands are manufactured with a very high copper purity to accurately transmit the impulse frequencies through the coils and into the water to induce a physical change to mineral scale.

This is NOT a magnet or electromagnetic field device.

KASHYAP technology uses proprietary impulse frequency distributions.

Impulse frequency technology does not rely on water flow, like magnets; this means mineral change is constant, stable and robust. Learn more about the differences…

Specifications

Device:

Max. Pipe Diameter: 14 inchesMax. Water Flow: 1,541 GPM

Dimensions: 11.8" x 15.7" x 5.5"

Programs: 6

Impulse Bands:

Impulse Bands: 10 x 52.4 feet longSpace Required: ~9.8 feet

power supply image

Power Supply Unit:

Watts: 2.75In: 87-260 Volt | 50-60 Hz

Out: 24 Volt | 600 mA

Packaging Image

Packaging:

Dimensions: infoWeight: info

Questions?

Ask a question about the Kashyap impulse frequency mineral descaler >>>How do I install the K-200 mineral descaler?

The copper impulse bands are wrapped around the outside of a water pipe. Mount the control box on the water pipe using the C shaped bolts or place the device on a stable surface. Plug the impulse bands into the device and the power cord into the control box.How long is this warranty and what does it cover?

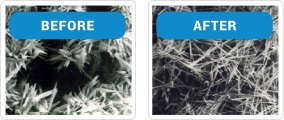

The impulse frequency mineral descaler is warranted for 5 years against all manufacturing defects. Once the device is installed there is no reason to adjust configurations or maintain any processes; it works continuously to alter mineral scale bonds. The device only uses 2 watts of energy, about $10 per year.Why do minerals scale bonds change back into their original shape after 1-7 days?

Wobbling impulse frequencies cause minerals to change from spiky sphere-shaped structures into smooth rod-shaped crystals due to the energy transmitted in the frequency impulses. This molecular mineral energy has a lifespan from initial contact. The warmer the water passing through the impulse frequency coils the stronger the reaction. There is more inherent energy in hot water than cold water and this is why bonds keep their smooth rod-shaped appearance up to, and after, 7 days in hot water.Why do bonds only hold together for 1-2 days in cold water and up to 7 days in hot water?

There is more inherent energy in hot water than cold water and this is why bonds keep their smooth rod-shaped appearance up to, and after, 7 days in hot water.How old is this technology?

Impulse frequencies have been used to physically treat the effects pf hard water mineral scaling for over 40 years. Over the last 4 decades major advances have improved the technology to allow progressively larger pipe diameter treatments without needing to cut, damage or remove water pipes to physically treat water at the point of contact and the impact of water throughout a building/ facility.Does my company need more than 1 device?

Depending on the size of your business environment and the purpose for installing the mineral you may need 1 or multiple devices. The K-300 mineral descaler supports a pipe diameter of 14 inches.One K-350 installation:

Example: industrial application to support very high water flow rates.

Multiple device installation:

Example: a CCM operation (Continous Casting Machine) requiring excessive mineral scale removal to support efficient manufacturing operations.

Solution:

10 inch water line with over 1,200 GPM: Although the K-200 can support a pipe diameter up to 10 inches, the max. water flow rate is 1,100GPM. If your industrial operations require a faster water flow rate, a larger Kashyap mineral descaler is required. In this case the K-350 model will work as it supports up to 1,541 GPM water flow.

If your company has multiple Continous Casting Machines (CCM) a separate mineral descaler may be required to support each machine an operation.

If you need help choosing the right size or would like help developing an installation plan for your company and operating environment please contact us at Sales@USdescaler.com