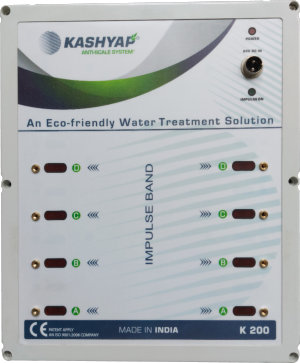

Impulse frequency technology prevents, removes and protects your company and building from the destructive effects of mineral scale build-up and rust damage.

HOW DOES MINERAL SCALE IMPACT YOUR COMPANY?

Using clean water in your company extends beyond the actually quality of the water to include the state of the delivery pipes and the equipment it flow in-and-out of. Mineral scaling, rust deposits and biofilm all contribute to impaired water quality, significantly lower equipment efficiencies and unnecessary energy demands. Dirty internal pipes and internal equipment components promote heath issues such as Legionnaires' disease, other illnesses and excessive biofilm since pathogens use mineral scale as a food source.Removing mineral scale is the first step towards sanitizing your building’s water pipes and mechanical equipment, and supporting climate action to use less energy to lower GHG levels. The descaling process is gentle and does not damage water pipes or equipment; it will take a few weeks to months to remove mineral scale from your entire building without requiring labor demands or continuous maintenance.

In 2013 the US Department of Energy (DOE) commissioned a research study (under contract DE-AC05-76RL01830) to identify the “Impacts of Water Quality on Residential Water Heating Equipment”. The investigation proved that mineral scale directly impacts equipment performance, energy usage and longevity.

PREVENTS

mineral scale from bonding to surfaces by changing their molecular shape into rod-shaped structuresREMOVES

existing hard water mineral scale and rust using impulse frequency technology developed over 20+ years of testingPROTECTS

metal surfaces against future corrosion by creating a metal-carbonate layer as a result of an electrophoresis reaction

Cooling Towers

Mineral scaling is a type of fouling that impacts a cooling tower operational efficiency. Remove scale fouling without using chemicals, salt, filters or labor maintenance by using impulse frequency technology.KASHYAP: case studies

Heat Exchangers

Mineral scaling cannot be blasted off a heat exchanger (PHE) with a pressure hose because the minerals bond to surfaces. This technology uses proprietary impulse frequencies to prevent mineral bond adhesion and flushes scale and rust away.KASHYAP: case studies

Chillers

Mineral scale deposits increases thermal resistance because elements become covered with a solid layer that the heating/ cooling energy needs to penetrate. This increased demand required more consistent energy straining chillers and costing more to operate.KASHYAP: case studies

Condenser Tubes

Installing an impulse frequency mineral descaler before condenser tube equipment will remove and prevent scaling without using chemicals, requiring cleaning maintenance and incurring downtime.KASHYAP: case studies

Circulating Pipes and Pumps

Controlling mineral scaling build-up in circulating pipes and pumps by incorporating electronic wobbling impulse frequency technology to prevent minerals from bonding to surfaces.KASHYAP: case studies

Evaporative Condenser

Refrigeration systems remove heat from buildings in summer months and an increase in scale has been directly linked to an increase in equipment energy demands.KASHYAP: case studies

Air Handling Unit

Water out of a laboratory is more than H2O and contains essential minerals (Ca, Mg, etc.) including pathogens because our water supply is not pure. When you remove scale you also establish cleaner equipment and a heathier building environment.KASHYAP: case studies

HVAC

Using chemicals treatments to remove mineral scaling is not a sustainable solution for mitigating the long or short term impacts because at just 1mm thickness scale can cause an increase of 15% in energy demands.KASHYAP: case studies

Water Pipe Systems

Looking for possible internal locations where scale buildup may be occluding is an ineffective action plan. Use technology to automatically and continuously clean your entire building’s piping system and internal components.KASHYAP: case studies

QUICK Facts:

- Does not use magnetic fields or electromagnetic technology

- Bonds last for 1-7 days depending on the water temperature

- Effective up to over ½ mile (1 km) from the point of treatment

- Works on any pipe material: copper, metal, PVC, PEX, compound

- Standard models are available for pipes up to a 40" diameter.

Larger pipe diameters can be custom produced, example.