Impulse frequency technology prevents, removes and protects your company and building from the destructive effects of mineral scale build-up and rust damage.

HOW DOES MINERAL SCALE IMPACT YOUR OPERATIONS?

Reducing facility downtime, lowering maintenance requirements to remove scale formations, and lowering energy costs can be achieved by incorporating proven mineral descaling impulse frequency technology.The Kashyap impulse frequency technology has been used in huge corporation and power plant facilities to mitigate the impact mineral scaling has on mechanical equipment. The technology works by preventing minerals from bonding to surfaces thereby alleviating the problem before it even begins.

The influence of mineral scale build-up has been documented in multiple countries, publication and research studies; including the United States Department of Energy.

Removing mineral scale is the first step towards sanitizing your facility's water pipes and mechanical equipment, and supporting climate action to use less energy to lower GHG levels. The descaling process is gentle and does not damage water pipes or equipment; it will take a few weeks to months to remove mineral scale from your entire building.

In 2013 the US Department of Energy (DOE) commissioned a research study (under contract DE-AC05-76RL01830) to identify the “Impacts of Water Quality on Residential Water Heating Equipment”. The investigation proved that mineral scale directly impacts equipment performance, energy usage and longevity.

DEMONSTRATED SUCCESS

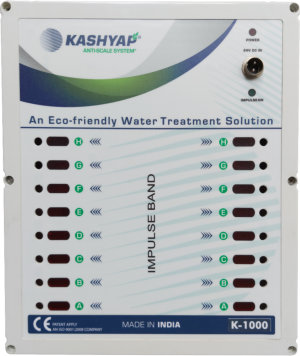

wobbling impulse frequency distribution positively impacts industrial operations

PREVENTS

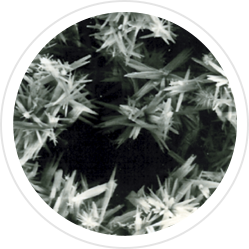

mineral scale from bonding to surfaces by changing their molecular shape into rod-shaped structuresREMOVES

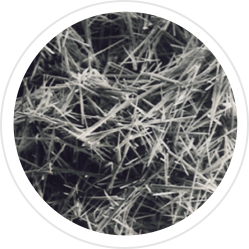

existing hard water mineral scale and rust using impulse frequency technology developed over 20+ years of testingPROTECTS

metal surfaces against future corrosion by creating a metal-carbonate layer as a result of an electrophoresis reactionQUICK Facts:

- Does not use magnetic fields or electromagnetic technology

- Bonds last for 1-7 days depending on the water temperature

- Effective up to over ½ mile (1 km) from the point of treatment

- Works on any pipe material: copper, metal, PVC, PEX, compound

- Standard models are available for pipes up to a 40" diameter.

Larger pipe diameters can be custom produced, example.